What is ISPM 15? The Complete Guide to the International Wood Packaging Standard

ISPM15 is one of the most important standards in international trade, especially related to the packaging and transportation of wooden goods. This standard is issued to prevent pests from spreading through wooden materials, protecting the environment and the global ecosystem. With a mandatory role in many countries, ISPM15 becomes the key for import and export businesses to ensure legal compliance. This article will help you understand ISPM15, how to apply it and the benefits of following the regulations!

What is ISPM 15?

ISPM15 (International Standards for Phytosanitary Measures No.15) is an international standard issued by IPPC - International Plant Protection Convention. The main objective of this standard is to prevent the spread of pests and harmful organisms through wooden materials used in packaging and international transportation of goods.

The ISPM15 standard specifies wood treatment methods such as heat treatment (HT) or fumigation with Methyl Bromide (MB) gas to kill pathogens. After treatment, the wood must be stamped with ISPM15 with information about the country, manufacturer and treatment method.

This is one of the mandatory requirements when exporting goods using wooden pallets, wooden crates or wooden dunnage materials to many countries. Compliance with ISPM15 not only helps businesses avoid the risk of returned goods and customs fines, but also contributes to protecting the environment and the global ecosystem.

Scope and applicable materials

1. Wood packaging material (pallets, crates, dunnage, ...)

ISPM15 applies to most types of natural wood packaging materials that have not been deeply processed. Including:

- Wooden pallets used to support and transport goods.

- Crates (wooden boxes, wooden boxes) used to protect bulky goods.

- Dunnage (wooden wedges, wooden wedges, wooden blocks) helps to secure goods in containers.

- Wooden cable, wooden roll boxes or similar wooden structures.

The common point of these materials is that solid wood is capable of carrying pathogens, so it needs to be treated and marked ISPM15 before international circulation.

2. Exempted materials (processed wood under 6 mm, plywood, OSB ...)

Not all wood must comply with ISPM15. Some materials are exempted because they have been industrially processed and no longer pose a risk of carrying pathogens, for example:

- Thin wood under 6 mm (thin wood).

- Plywood (plywood).

- OSB (Oriented Strand Board) and MDF (Medium Density Fiberboard).

- Pressure/heat treated plywood, particleboard or other artificial wood types in production.

- Finished wood products such as furniture, wooden household goods.

This classification helps reduce costs and time for businesses, while focusing control on high-risk materials during international transportation.

ISPM15 treatment requirements

1. Heat Treatment (HT: 56 °C ≥ 30 minutes)

In the ISPM15 standard, the most common method for treating wood packaging is heat treatment (HT). Wood must be placed in a specialized heat chamber or oven to ensure that the core temperature reaches a minimum of 56 °C and is maintained continuously for at least 30 minutes. This process helps to destroy insects, molds and potential pests in the wood material. Once completed, the wood is considered safe for circulation in international trade.

2. Gas treatment (Methyl Bromide – MB: CT dosage, temperature)

In addition to HT, ISPM15 also accepts the fumigation method with Methyl Bromide (MB). This is a chemical that can penetrate deep into the wood structure, destroying pathogens and insects. However, the use of MB is closely monitored due to its impact on human health and the environment. Dosage, contact time and temperature must comply with international standards, otherwise it will be considered invalid.

3. Additional methods (dielectric heating, SF, etc.)

Along with the two main methods, ISPM15 also allows some new treatment solutions such as dielectric heating (heating by microwave or high frequency) or using safer alternative gases. These methods are being researched and applied in some countries to replace MB, reduce environmental impact but still ensure the effectiveness of pest control in wood.

ISPM15 marking requirements and structure

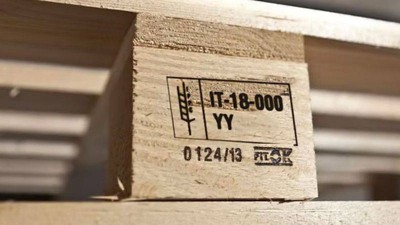

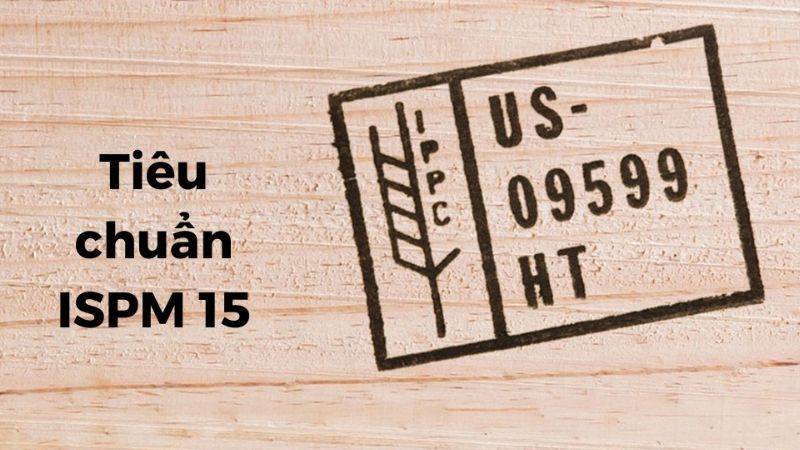

1. Mark structure: IPPC logo, country code, unit code, treatment code

After the wood has been treated according to ISPM15 standards, the packaging must be properly stamped. The structure of the mark includes:

- IPPC (International Plant Protection Convention) symbol.

- ISO country code (e.g. VN for Vietnam, US for the United States).

- Processing unit code – issued by the national plant protection agency.

- Treatment method – abbreviated as HT (Heat Treatment) or MB (Methyl Bromide).

2. Positioning, legibility and retention of the mark (legibility, durability, visibility)

The ISPM15 mark must not only be structurally correct but also visible, durable and clear. Typically, the mark is printed or engraved on an easily observable surface of a pallet, wooden crate, or package. The requirement is that the mark does not fade during transport, cannot be erased or edited to avoid fraud. If the wooden packaging is reused or repaired, the mark must be replaced or supplemented in accordance with regulations.

Roles and Responsibilities of NPPOs

1. Approval of Treatment and Production Facilities

Under ISPM15, each country’s NPPO (National Plant Protection Organization) is responsible for licensing and approving facilities that are authorized to process wood. This includes pallet factories, fumigation facilities, and heat treatment service providers.

Approval typically involves testing the technical capabilities, equipment, and processes to ensure compliance with international standards. Once accredited, these facilities are authorized to affix the ISPM15 mark to wood packaging materials for use in international trade.

2. Monitoring, inspection, verification, and non-compliance

NPPOs not only provide initial approval, but also maintain regular monitoring activities. On-site inspections, process reviews, and ISPM15 mark verification help ensure consistent quality. If an invalid mark, improper handling or commercial fraud is detected, the NPPO may revoke the permit, impose administrative penalties, or notify the international IPPC system.

Practical Operation and International Examples

1. Enforcement in the United States (APHIS, Conformity Import)

In the United States, the APHIS (Animal and Plant Health Inspection Service) is the agency directly managing the import of wood packaging according to the ISPM15 standard. All pallets, wooden crates, and dunnage materials must have the conformity mark before entering the country. US Customs regularly checks for the ISPM15 mark at the port of entry. N

If violations are detected, the shipment may be refused entry, required to be reprocessed or re-exported. This is a typical example of ISPM15 being strictly applied to protect agriculture and native ecosystems.

2. Practice in Vietnam (date of application, NPPO Vietnam…)

In Vietnam, NPPO is the Plant Protection Department under the Ministry of Agriculture and Rural Development. Vietnam officially implemented ISPM15 since 2005, according to its commitment to IPPC. Wood pallet and wood packaging manufacturing facilities must register and be granted a processing code by the Plant Protection Department. The monitoring system is maintained through periodic inspections and re-issuance of certificates.

In export, if a shipment lacks the ISPM15 mark or has an incorrect mark, many markets such as the US, EU, and Japan will refuse to import, causing great damage to businesses. Therefore, compliance with ISPM15 in Vietnam is not only a legal requirement, but also a key factor in helping goods circulate smoothly in the international market.

Common issues and notes

- Repair, reuse and remanufacture: When ISPM15 treated pallets or wood packaging are repaired or reused, they need to be inspected and re-marked. If too many parts are replaced, the entire shipment must be re-treated and a new mark issued.

- Substandard packaging and risks: In some cases, overlapping, blurred or incorrect marks cause the shipment to be considered ineligible. The consequences can lead to import rejection, destruction or return of goods, causing damage to costs and time for businesses.

Summary

ISPM15 is an important international standard that helps control wood packaging materials in trade, limiting the risk of spreading pests across borders. Compliance with ISPM15 not only ensures that goods are cleared through customs smoothly but also enhances the reputation of businesses in the international market. Correctly implementing treatment and marking requirements helps minimize the risk of violations, save on storage costs and avoid returns. Compliance with ISPM15 is key for businesses to participate in global supply chains in a sustainable manner.