Summary of Vietnamese and international standard pallet sizes - latest update

Are you wondering what the standard pallet size is to suit your shipping and storage needs? Choosing the right pallet size not only helps optimize warehouse space but also ensures safety when loading and unloading. There are many different standards such as European, Asian or GMA, which can easily confuse users. The following article will help you understand the common sizes and how to choose the right pallet!

What is a pallet? Why should you care about standard sizes?

A pallet is a flat structure, usually made of wood, plastic or metal, used to support goods for convenient lifting, lowering and transporting by forklift, hand pallet truck or conveyor system. In the logistics chain, pallets play an important role in optimizing storage, reducing loading and unloading time and protecting goods from damage.Choosing the standard pallet size not only helps businesses ensure synchronization in warehouse operations but also increases compatibility with containers, shelves and lifting equipment. Using the wrong size can result in wasted space, difficulty in transportation, or even additional system adjustment costs.

Choosing the standard pallet size not only helps businesses ensure synchronization in warehouse operations but also increases compatibility with containers, shelves and lifting equipment. Using the wrong size can result in wasted space, difficulty in transportation, or even additional system adjustment costs.

Popular standard pallet sizes today

1. European standard pallet size (EPAL)

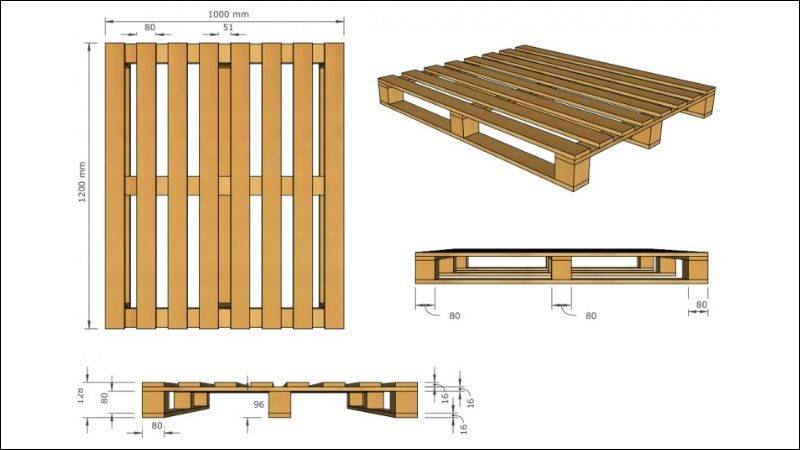

In Europe, the EPAL (European Pallet Association) system specifies the most popular standard size as 1200 × 800 mm. This type of pallet is suitable for common shelves and forklifts in the European market. In addition, there are some other variations such as 1200 × 1000 mm or 600 × 800 mm for special needs.

2. GMA standard pallet size (North America)

In North America, especially the United States and Canada, the standard pallet size is often called GMA (Grocery Manufacturers Association) with the parameters 1219 × 1016 mm (equivalent to 48 × 40 inches). This type of pallet accounts for more than 30% of the total pallets used in this region, thanks to its flexibility and stable load capacity.

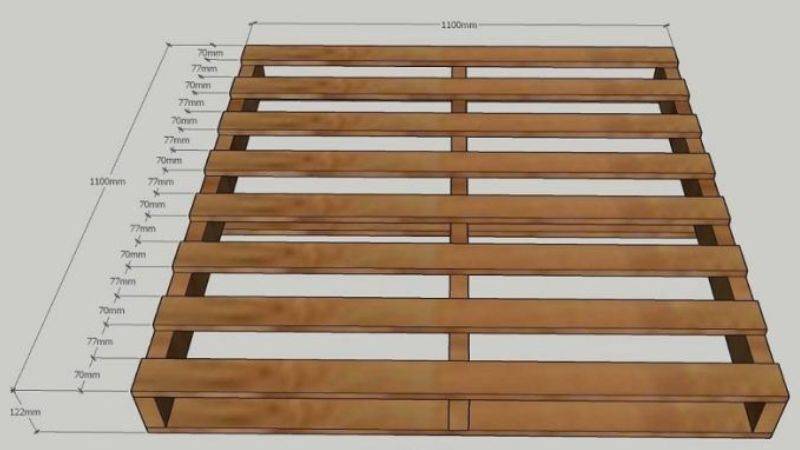

3. Asian standard pallet sizes (1000×1200, 1100×1100 mm)

The Asian region uses more sizes depending on the country, but the most popular are two types: 1000 × 1200 mm and 1100 × 1100 mm. Of which, the square size of 1100 × 1100 mm is often preferred because it is easy to rotate in containers and optimizes the stacking space.

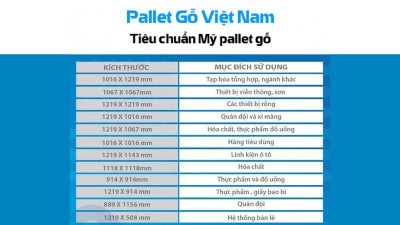

4. Standard pallet sizes in Vietnam

In Vietnam, businesses often use pallets with flexible sizes, however, 1000 × 1200 mm and 1100 × 1100 mm are still two popular standards in warehousing and export. In addition, some industries also order pallets in specific sizes to suit packaging specifications, helping to optimize the area for transporting and storing goods.

Compare the size of wooden pallets and plastic pallets

Wooden pallets and plastic pallets both have many standard sizes to meet the needs of use in transporting and storing goods. However, depending on the material and actual application, these types of pallets will have certain differences in size, flexibility and compatibility with loading and unloading equipment.

1. Common size table of wooden pallets

Wooden pallets are usually produced according to the following standard sizes:

- 1200 x 1000 mm: popular in Asia, suitable for forklifts and standard shelves

- 1200 x 800 mm: according to European standards (EPAL), widely used in export markets

- 1100 x 1100 mm: commonly seen in the chemical and food industries

- 1000 x 1000 mm: flexible use in small and medium-sized warehouses

These sizes help optimize storage space and are suitable for common means of transport.

2. Common size table of plastic pallets

Plastic pallets have high precision in size due to being manufactured according to molds. Some common sizes:

- 1200 x 1000 mm: multi-industry applications, easy to combine with containers

- 1100 x 1100 mm: used in cold storage and food environments

- 1200 x 800 mm: compatible with European industrial shelf standards

- 1300 x 1100 mm: large pallets for bulky goods

3. Should you choose wooden pallets or plastic pallets according to the purpose of use?

The choice between wooden pallets and plastic pallets depends on the specific purpose of use:

- Wooden pallets: suitable for heavy goods, low cost, easy to repair, but less durable in humid or cold storage environments.

- Plastic pallets: ideal for environments requiring high hygiene such as food, pharmaceuticals, have a long life and are lighter, but are more expensive and difficult to repair.

Therefore, for the export industry or regular warehouse operations, wooden pallets are an economical solution; while for industries that require long-term stability and strict hygiene standards, plastic pallets are more suitable.

Pallet size by industry and purpose of use

Not all industries use the same type of pallet. Pallet size needs to be selected to suit the type of goods, means of transport, and storage standards of each field.

1. Pallets used in industrial warehouses and logistics

In warehouses and logistics systems, pallets of sizes 1200 x 1000 mm and 1100 x 1100 mm are popular choices because they are suitable for forklifts, containers and standard shelves. Pallets need to have good load capacity, uniform size and easy to handle when moving goods.

2. Pallets used in the food and pharmaceutical industry

The food and pharmaceutical industry requires high hygiene standards, so plastic pallets with sizes such as 1100 x 1100 mm or 1200 x 800 mm are often preferred. Pallet models need to be easy to clean, waterproof and not rotten due to humid environments or cold storage.

3. Pallets for the agricultural and export industries

The agricultural and export industries require pallets that have good load-bearing capacity, are easy to stack, and are compatible with international containers. Common sizes are 1200 x 1000 mm (Asia) or 1200 x 800 mm (Europe). In addition, wooden pallets must comply with ISPM 15 regulations to be accepted in international transportation.

International standards related to pallet size

Using the right size pallet not only ensures efficient transportation and storage but also helps businesses comply with international standards when exporting goods. Worldwide, there are many different sets of standards regulating pallet sizes, of which ISO 6780 is the most important foundation, along with a number of other popular technical standards such as ISPM 15, DIN or JIS.

1. ISO 6780 - global pallet size standard

ISO 6780 specifies six main pallet sizes recognized globally, to ensure consistency when transporting goods between regions. Each size is designed to suit the type of container, vehicle and warehouse system popular in regions such as Europe, Asia, North America, etc. Complying with ISO 6780 helps businesses easily connect the supply chain and optimize logistics costs.

2. Additional standards (ISPM 15, DIN, JIS...)

In addition to ISO 6780, there are other technical standards applied in some specific fields or countries. ISPM 15 is a standard for heat treatment of wooden pallets when exporting to prevent pests, which is required in many countries. DIN (Germany) and JIS (Japan) are separate systems of technical and dimensional standards, often applied domestically or with partners using the same system. Understanding and correctly applying these standards will help goods circulate smoothly in the international market.

Frequently asked questions about standard pallet sizes (FAQ)

1. Can pallets be ordered in custom sizes?

Yes. Many manufacturers accept custom pallet designs to suit the size of goods or warehouse space of the business.

2. Can standard pallets be used for all containers?

Not necessarily. Each type of container has a different size, so it is necessary to choose the right pallet to optimize the area and avoid wasting space.

3. How often should the pallet's durability be checked according to the load?

It is recommended to check periodically every 3-6 months, especially for pallets used frequently or in humid, heavy-duty environments. This helps ensure safety and prolong the life of the equipment.

Conclusion

Choosing the right standard pallet size helps optimize storage space, ensure safety in transportation and is suitable for goods handling equipment. Each industry and region has different standards, so consider carefully before using. Do not choose the size based on feelings, but base it on actual needs and international standards. This not only saves costs but also improves logistics efficiency.