Guide to Choosing ISPM-15 Standard Export Pallets: Wood or Plastic, Size

Export pallets are one of the important factors that help businesses optimize the transportation process and ensure smooth customs clearance. Choosing the right type of pallet, the right size and meeting international standards not only helps save logistics costs but also minimizes the risk of returned goods. In the context of increasingly strict global trade, understanding export pallets is the key for businesses to improve their competitiveness.

What are export pallets?

Export pallets are pallets manufactured and processed according to international standards, used to support, lift and secure goods during the transportation process abroad. Unlike domestic pallets that only need to meet simple storage or loading and unloading needs, export pallets must ensure strict regulations on plant quarantine, materials and specifications. This helps keep goods safe when crossing the border, while avoiding risks arising from customs clearance.

Why do export goods need to use standard pallets?

1. Meet international quarantine regulations (ISPM-15, HT, MB)

Most importing countries require wooden pallets to comply with ISPM-15 standards. This standard requires pallets to be heat treated (HT) or fumigated with Methyl Bromide (MB) gas to eliminate pests and mold. If the pallet does not have the ISPM-15 certification mark, the shipment may be detained or returned, causing great damage to the business.

2. Limit the risk of returning goods or being fined during customs clearance

Many cases have been fined or forced to re-export simply because the pallet does not meet the required specifications. A standard export pallet helps businesses feel more secure when carrying out customs procedures, reduces the risk of congestion, and protects reputation in international transactions.

3. Optimize transportation and storage costs

In addition to legal factors, standard pallets are also designed with appropriate sizes and loads according to each market (EU, US, Japan, etc.). Thanks to that, container loading and unloading is more efficient, reducing excess space and optimizing transportation costs. Moreover, standard pallets help protect goods better in warehouses, limit damage and save storage costs.

Popular types of pallets for export goods

1. Traditional wooden pallets

Wooden pallets are the traditional choice, accounting for the largest proportion in international transportation. Commonly used materials include rubber wood, cajuput wood, pine wood, etc. The advantages of wooden pallets are low cost, good load-bearing capacity and easy production in many different sizes. However, to be used for export, wooden pallets must be treated against termites, disinfected and stamped with ISPM-15 to meet the quarantine requirements of customs of importing countries.

2. Plastic pallets (PP, HDPE…)

In recent years, plastic pallets have been prioritized by many businesses when packing export goods. They are often made of PP or HDPE plastic, with the advantages of high durability, moisture resistance, easy cleaning and no need for sterilization like wood. The biggest disadvantage is that the cost is higher, difficult to repair when damaged. Plastic pallets are suitable for goods that require cleanliness, food, pharmaceuticals or high-value items.

3. Paper pallets & metal pallets (less common but available in special cases)

In addition to the above two types, paper pallets and metal pallets are also used for export goods but to a limited extent. Paper pallets have the advantage of being light, environmentally friendly, suitable for light goods or air exports. Metal pallets, usually steel or aluminum, are extremely durable, can withstand large loads but are expensive, mainly for special industries such as mechanics, heavy machinery.

4. Molded wooden pallets

In the group of export pallets, molded wooden pallets are considered a popular solution thanks to their strength and high load-bearing capacity. This type of pallet is made from wood chips, shavings or sawdust compressed under high pressure, forming a uniform and durable structure. Thanks to the hot pressing process, molded wooden pallets are moisture resistant, termite resistant and meet international quarantine standards, especially ISPM-15. This is a suitable choice for businesses that need to transport large quantities of goods to international markets at reasonable costs and high reliability.

Mandatory standards for export pallets

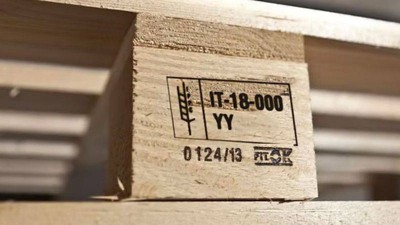

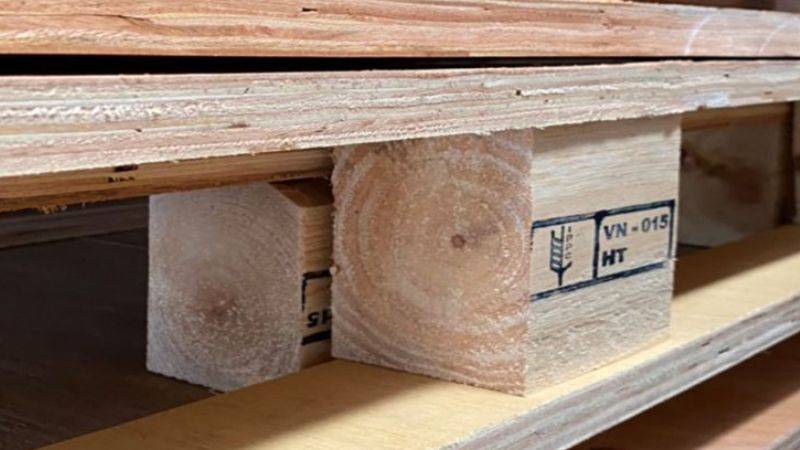

1. ISPM-15 standard

ISPM-15 is an international standard issued by the FAO to control pests spread through wood materials. Accordingly, wooden pallets used for export must be heat treated or fumigated and certified. Compliance with ISPM-15 helps goods clear customs smoothly, avoiding returns or destruction at the port of arrival.

2. Treatment methods: Heat Treatment (HT) and Methyl Bromide (MB)

There are two common methods:

- HT (Heat Treatment): heat treatment at 56°C for at least 30 minutes to kill pathogens. This is an environmentally friendly method, most widely used.

- MB (Methyl Bromide): fumigation with chemical gas. This method is fast but many countries have now limited it due to its impact on health and the environment.

3. Regulations on size and load

In addition to disinfection treatment, pallets for export goods must comply with the size regulations for each market:

- Europe (EUR pallet): 1200×800 mm

- America (GMA pallet): 1219×1016 mm

- Asia: 1100×1100 mm or 1200×1000 mm

The load of the pallet must also be clearly inspected: static load, dynamic load and load when stacking shelves. Using the correct specifications helps keep goods safe, saves container space and complies with international logistics standards.

International standard pallet size

1. EU standard (EUR 1, EUR 3…)

In the European market, pallets for export goods often follow the EUR-pallet system. The most common size is EUR 1 (800 × 1200 mm), suitable for most types of containers and warehouses in the EU. In addition, EUR 3 (1000 × 1200 mm) is also widely used to optimize space for bulky goods. These sizes help businesses exporting to Europe easily clear customs, avoiding rejection at import ports.

2. American standard (40 × 48 inches)

In the US, the most popular pallet standard is 40 × 48 inches (1016 × 1219 mm). This type of pallet accounts for more than 70% of the US logistics industry, suitable for many types of goods from food, beverages to consumer goods. When choosing pallets for export to the US, businesses need to prioritize this type of pallet to ensure efficient loading, unloading, storage and transportation.

3. Popular sizes in Asia (1100×1100 mm, 1200×1000 mm)

In Asian countries, especially Japan, Korea and Vietnam, pallets with sizes of 1100×1100 mm and 1200×1000 mm are commonly used. These sizes are optimal for 20-foot and 40-foot containers, helping to maximize shipping space. This is also a safe choice for businesses exporting to many different markets, thanks to its flexibility and high compatibility.

Advantages of each type of pallet

1. Comparison of wooden pallets and plastic pallets

- Wooden pallets: Low cost, easy to produce, good load-bearing capacity. However, wooden pallets are often heavy, susceptible to termites and require ISPM-15 fumigation before export.

- Plastic pallets: Durable, light, mold-resistant and do not require fumigation. The downside is that the cost is higher, and in some cases it is not suitable for very heavy goods.

2. One-way pallets for export

For export goods that do not require pallet recovery, businesses often use one-way pallets. This type of pallet is cheap, often made from mixed wood or recycled plastic. However, one-way pallets should only be used for one-way shipments that do not require reuse.

3. Cost and durability factors by type

- If low cost and one-time transportation are the priority: one-way wooden pallets are a reasonable choice.

- If long-term reuse and hygiene are required (food and pharmaceutical industries): plastic pallets are more optimal.

- Businesses should consider initial costs, lifespan and export requirements to choose pallets suitable for each market.

How to choose the right pallet for your export business

1. Choose according to the export market (EU, US, Japan, etc.)

Each country and region has its own standards for pallets for export goods. For example, the EU often uses the size 800×1200 mm (EUR 1), the US popularizes the 40×48 inch type, while Japan prefers 1100×1100 mm. If the business chooses the wrong specification, the goods may be rejected during customs clearance. Therefore, before ordering pallets, it is necessary to clearly identify the target market to choose the appropriate size and standard.

2. Choose according to product and load

Not all types of goods need the same type of pallet. Heavy goods (machinery, rolled steel) need high-strength wooden pallets, while light, fragile goods (food, pharmaceuticals) are often suitable for plastic or paper pallets. Businesses need to calculate the static and dynamic loads to choose the optimal pallet, avoiding wasted costs or the risk of damaged goods.

3. Criteria for choosing a reputable pallet supplier

A quality supplier not only ensures the correct specifications but also has ISPM-15 certification and stable delivery capacity. Enterprises should prioritize units with export experience, providing consulting services, supporting inspection and printing logos/marks as required. This helps limit risks when goods pass through international border gates.

Notes when buying export pallets

1. Check ISPM-15 certification

This is a mandatory regulation for pallets for wooden export goods. ISPM-15 requires heat treatment (HT) or fumigation (MB) to kill termites and mold. Substandard pallets can be destroyed right at the border gate, causing great damage.

2. Check the material and production quality

Whether wood or plastic, pallets need to be sturdy, not cracked, no bark and have a flat surface to avoid damaging the goods. With plastic pallets, it is necessary to ensure that PP/HDPE raw materials are of good quality, have the ability to withstand force and moisture.

3. Order according to specifications to avoid risks

Enterprises should order according to the standard size of the import market, and at the same time determine the appropriate quantity for each shipment. Before signing the contract, it is necessary to check the pallet sample and warranty terms. Ordering according to specifications helps save logistics costs and avoid having to change pallets urgently when exporting.

Conclusion

It can be seen that international pallets. Understanding ISPM-15 standards, choosing the right materials and working with reputable suppliers will help businesses save costs, optimize logistics and limit risks. Therefore, investing in standard pallets is a strategic step for export businesses to develop sustainably and expand the market.