What is a wooden pallet? Standard sizes, advantages and disadvantages and common applications

Wooden pallets are a popular solution for transporting and storing goods thanks to their durability, high load-bearing capacity and ease of reuse. Greenovation Packaging is a pioneer in providing environmentally friendly molded wooden pallets, meeting export standards and diverse business needs. Let's refer to the article to better understand the advantages, prices and reputable wooden pallet purchasing addresses!

What are wooden pallets & material classification

Wooden pallets are a type of frame or pallet made from wood, used to support, fix and transport goods in warehouses or when loading and unloading by forklifts and cranes. The sturdy structure of wooden pallets helps protect goods, while optimizing the storage and transportation process. This is a popular solution in many industries such as logistics, manufacturing, import and export thanks to its durability and ability to be reused many times.

In terms of material classification, wooden pallets can be divided into main groups:

- Natural wooden pallets: Made from acacia, eucalyptus, pine or other types of planted forest wood. This type has high durability, good load-bearing capacity and is easy to process according to required dimensions.

- Pressed wooden pallets: Use sawdust or pressed wood chips combined with specialized glue to form a uniform pallet. The advantages are light weight, flat surface, less warping.

- Molded wooden pallets: Made from wood chips, sawdust that have been hot-pressed in a mold to form a monolithic block. This type has good termite resistance, meets ISPM-15 standards, so it is prioritized for export.

Standard size & load capacity

1. ISO standards and common areas of use

Wooden pallets are manufactured according to many different standards, of which ISO (International Organization for Standardization) is the most popular system in the world. This standard specifies the dimensions, structure and load-bearing capacity to ensure uniformity in the storage and transportation of goods.

Currently, ISO standard wooden pallets usually have 6 main sizes: 1200x1000 mm, 1200x800 mm, 1140x1140 mm, 1100x1100 mm, 1067x1067 mm and 1016x1219 mm. Each size is preferred for use in different regions:

- Europe: 1200x800 mm (Euro Pallet)

- Asia: 1100x1100 mm or 1200x1000 mm

- North America: 1016x1219 mm (GMA Pallet)

Choosing the right standard helps businesses optimize container space, ensure safety during loading and unloading and reduce logistics costs.

2. Popular sizes in Vietnam and for export

In Vietnam, wooden pallets are often produced in sizes that meet domestic needs and the requirements of international partners. Popular sizes include:

- 1200x1000 mm - suitable for storing goods in warehouses and transporting domestically.

- 1100x1100 mm - optimal for 20ft and 40ft containers, used by many export enterprises.

- 1200x800 mm - meets European market requirements.

- 1140x1140 mm - used for the beverage, chemical, and products that require high load stability.

In terms of load, wooden pallets usually withstand from 500 kg to 1500 kg depending on the type of wood, board thickness and construction. For export goods, pallets need to be heat treated or fumigated according to ISPM 15 standards to meet customs regulations of countries.

Criteria for choosing suitable wooden pallets

1. Purpose of use: warehouse, export, interior, one-time use...

Before buying wooden pallets, you need to clearly define the purpose of use to choose the right type.

- Storage: You should choose wooden pallets with high load-bearing capacity, good moisture resistance, sturdy design for frequent lifting and lowering by forklift.

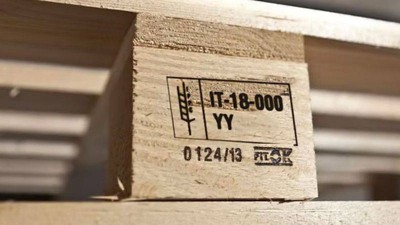

- Export: Prioritize wooden pallets that have been heat-treated or fumigated according to ISPM-15 standards, helping to meet international customs regulations and avoid returns.

- Interior, decoration: Choose new or surface-treated wooden pallets with few defects, uniform color for easy painting, coating and construction.

- Single use: If only used to transport goods in a short time, light, cheap wooden pallets will save more costs.

2. Technical requirements: load, ISPM-15 treatment, design

Some important technical criteria when choosing wooden pallets:

- Load: Determine the average and maximum weight of goods to choose wooden pallets with suitable load-bearing capacity (static load, dynamic load).

- ISPM-15 treatment: Required for exported wooden pallets to destroy pathogens, pests, and ensure biosafety during international transportation.

- Design: Consider between 2-way or 4-way lifting wooden pallets, closed or open surface structure, number of wooden slats and board thickness suitable for the type of goods and loading and unloading method.

Reputable wooden pallet supplier

Greenovation Packaging is a pioneer in the production of environmentally friendly molded wooden pallets, aiming for green and sustainable transportation solutions. With a capacity of more than 3 million pallets/year, recycled wood materials and safe MDI glue, the company flexibly meets many needs in terms of size, load and export standards.

Featured products:

- 1-layer molded wooden pallet - light, easy to stack, suitable for light - medium transportation, space saving.

- 2-layer molded wooden pallet - sturdy structure, high load capacity, reusable many times, suitable for heavy goods.

- Flat molded wooden pallet - flat, solid surface, stable goods, ideal for the food, pharmaceutical and electronics industries.

Greenovation Packaging has achieved FSC, ISO 9001:2015, ISO 14001:2015 certifications

(HÌNH)

Conclusion

Wooden pallets are a sustainable choice, meeting the storage and transportation needs of many industries. With the advantage of modern production, environmentally friendly materials and international standards, Greenovation Packaging offers high-quality wooden pallet solutions, optimizing costs and ensuring the safety of goods. Contact Greenovation Packaging now to receive the latest wooden pallet price quote and advice on suitable solutions for your business!