Cold storage pallets: Detailed instructions for choosing cold storage pallets

Cold storage pallets are an indispensable solution for preserving goods in low temperature environments, ensuring quality and safe transportation. With the ability to withstand deep cold, prevent mold and high durability, cold storage pallets are suitable for many industries such as food, seafood, pharmaceuticals. Choosing the right type of pallet helps optimize storage space and improve logistics efficiency. Refer to the useful information in this article with Greenovation Packaging to choose the right cold storage pallet!

Why do we need specialized pallets for cold storage?

Cold storage is an environment for preserving goods at low temperatures, often fluctuating between 0°C and below -20°C. This condition not only affects product quality but also strongly affects the durability of storage and transportation equipment, including pallets. If using conventional pallets, the material may become brittle, cracked or warped due to changes in temperature and humidity.

Specialized pallets for cold storage are designed to withstand harsh environments, ensuring stable load-bearing capacity, limiting damage and maintaining the safety of goods. In addition, these pallets are often moisture-resistant, mold-resistant, and corrosion-resistant, helping to maintain hygiene and prolong the service life, especially important for the food, seafood and pharmaceutical industries.

Popular types of pallets for cold storage

1. Plastic pallets (HDPE/PP)

Advantages:

- Good cold resistance, not brittle and cracked at negative temperatures.

- Moisture-resistant, waterproof, not susceptible to termites or mold.

- Easy to clean, meeting food safety standards.

- Lighter weight than wooden or iron pallets, convenient to move.

Popular parameters:

- Material: HDPE or virgin PP.

- Static load: 3–5 tons.

- Dynamic load: 1–1.5 tons.

- Standard size: 1100 × 1100 × 150 mm (customizable upon request).

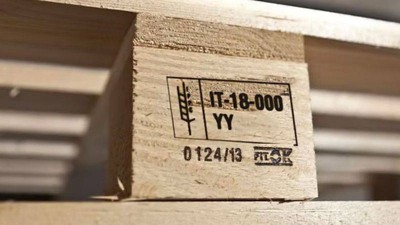

2. Wooden pallets

Advantages:

- Low cost, easy to manufacture and replace.

- Good load-bearing capacity.

- Size can be customized according to specific requirements.

When to use: Wooden pallets are only suitable for cold storage of goods that do not require high hygiene standards, or industries that have little direct contact with food. To increase the lifespan, moisture-proof treatment and surface coating should be applied.

3. Iron pallets

Advantages:

- Excellent durability, very high load-bearing capacity, no warping.

- Completely termite-free, good fire resistance.

- Suitable for harsh environments and super heavy goods.

Suitable application: Iron pallets are often used in cold storage for heavy goods, industrial goods or products that require extremely sturdy storage structures. When used in cold and humid environments, it is necessary to choose galvanized or powder-coated types to prevent rust.

Criteria for choosing cold storage pallets

1. Heat resistance (humidity, mold)

Cold storage pallets need to be made from materials that can withstand deep negative temperatures without becoming brittle, deformed or losing their structure. In addition to the temperature factor, the cold storage environment often has high humidity, which can easily create conditions for mold to grow if the material is not moisture-resistant. Therefore, high-quality HDPE or PP plastic pallets are often preferred due to their moisture resistance, chemical resistance and resistance to termites like wood.

2. Load (static, dynamic, on shelves)

Load is a factor that determines the safety of storing goods. Cold storage pallets need to meet three criteria: static load (when goods are placed on the pallet), dynamic load (when pallets are moved by forklift) and shelf load (when placed in a shelf system). Choosing a pallet with the right load capacity helps avoid warping, cracking or collapsing, ensuring the safety of personnel and goods.

3. Cleaning and maintenance

Cold storage, especially in the food and pharmaceutical industry, requires strict hygiene standards. Pallets should have a flat surface with few gaps to limit the accumulation of dirt and bacteria. Plastic pallets are often easier to clean because they can be washed with high pressure water, are waterproof and dry quickly. Regular maintenance helps extend the life of the pallet and ensures that it meets food safety requirements.

4. Lifespan and investment costs

A high-quality cold storage pallet can be used for many years if the right material is selected and properly stored. Although the initial cost may be higher, the long life and ability to be reused multiple times will help reduce the overall cost. Businesses should consider the cost, durability and long-term efficiency to make the optimal investment decision.

Quick Comparison – Key Features Summary

The comparison table below helps you clearly see the differences between popular cold storage pallets, from materials to load capacity and temperature conditions.

|

Criteria |

Plastic Pallet (HDPE/PP) | Wooden Pallet | Iron Pallet |

| Heat Resistance | Good, -30°C to +40°C resistant | Medium, prone to cracking at low temperatures | Excellent, no deformation |

| Moisture & Mold Resistance | 100%, non-hygroscopic | Low, prone to mold if not treated |

100% |

| Static/Dynamic Loads | 3–5 tons / 1–2 tons | 2–3 tons / 1–1.5 tons | 4–6 tons / 1.5–2.5 tons |

| Durability & Lifespan | High (8–10 years) | Medium (3–5 years) | Very high (10+ years) |

| Investment Costs | Higher than wood, lower than iron | Low | High |

| Maintenance | Easy to clean, low maintenance | Requires periodic mold treatment | Almost no need |

Suitable application: Iron pallets are often used in cold storage for heavy goods, industrial goods or products that require extremely sturdy storage structures. When used in cold and humid environments, it is necessary to choose galvanized or powder-coated types to prevent rust.

Criteria for choosing cold storage pallets

1. Heat resistance (humidity, mold)

Cold storage pallets need to be made from materials that can withstand deep negative temperatures without becoming brittle, deformed or losing their structure. In addition to the temperature factor, the cold storage environment often has high humidity, which can easily create conditions for mold to grow if the material is not moisture-resistant. Therefore, high-quality HDPE or PP plastic pallets are often preferred due to their moisture resistance, chemical resistance and resistance to termites like wood.

2. Load capacity (static, dynamic, on shelves)

Load capacity is a factor that determines the safety of storing goods. Cold storage pallets need to meet three criteria: static load (when goods are placed on the pallet), dynamic load (when pallets are moved by forklift) and shelf load (when placed in a shelf system). Choosing a pallet with the right load capacity helps avoid warping, cracking or collapsing, ensuring the safety of personnel and goods.

3. Cleaning and maintenance

Cold storage, especially in the food and pharmaceutical industry, requires strict hygiene standards. Pallets should have a flat surface with few gaps to limit the accumulation of dirt and bacteria. Plastic pallets are often easier to clean because they can be washed with high pressure water, are waterproof and dry quickly. Regular maintenance helps extend the life of the pallet and ensures that it meets food safety requirements.

4. Lifespan and investment costs

A high-quality cold storage pallet can be used for many years if the right material is selected and properly stored. Although the initial cost may be higher, the long life and the ability to reuse many times will help reduce the overall cost. Businesses should consider the price, durability and long-term efficiency to make the optimal investment decision.

Recommendations by industry

1. Food & pharmaceuticals

This is a group of goods that require high hygiene standards, the ability to withstand deep cold and not deform in subzero environments. HDPE/PP plastic pallets are the optimal choice because they ensure food safety, are easy to disinfect, are moisture-proof and non-corrosive.

2. Seafood & agricultural products

This industry often stores goods in deep cold temperatures, humid environments and has salt or chemicals from the storage process. High-quality plastic pallets or galvanized iron pallets are safe, anti-corrosion and long-lasting options, limiting breakage during loading and unloading.

3. Heavy, long-term goods

For large-volume products, long storage time, requiring structural stability, iron pallets are the leading solution. Outstanding load-bearing capacity, no warping, suitable for cold storage of machinery, equipment or bulky goods.

Tips to extend the life of pallets in cold storage

For pallets to operate durably in harsh cold storage environments, you need to pay attention to both the use and storage stages. First of all, choose pallets made from materials suitable for negative temperatures, such as HDPE or virgin PP, to limit breakage when the temperature drops. When stacking, distribute the load evenly, avoid placing goods in one place, causing the pallet to bend or crack.

In addition, pallets should be cleaned regularly to remove ice, grease or impurities that have accumulated over time, helping to keep the surface clean and avoid slipping. If the pallet is not used for a long time, store it in a dry, cool area and avoid direct sunlight to maintain the durability of the material.

Conclusion

Cold storage pallets play an important role in protecting and storing goods safely. Choosing the right type of pallet, using it properly and maintaining it regularly not only helps save on replacement costs but also ensures long-term cold storage operation efficiency. Investing in quality pallets and applying reasonable storage tips will bring sustainable benefits to businesses, both economically and in terms of work efficiency.