Fumigation-Free Pallets: Conditions, Benefits & Regulations You Need to Know Before Using

Fumigation-free pallets are becoming the optimal choice for many export businesses thanks to their ability to shorten customs clearance time and save on processing costs. However, not everyone clearly understands which types of pallets are exempt, the applicable conditions and related international standards. This article will help you understand the concept, characteristics and how to use fumigation-free pallets in accordance with regulations!

Which pallets are considered fumigation-free?

Not all wooden pallets need to be fumigated or heat-treated. According to the international standard ISPM15, some types of pallets are classified as “fumigation-free” because the nature of their materials and production processes ensure complete destruction of termites, molds, and insects. These types of pallets help save costs and shorten customs clearance times, especially suitable for exporting goods.

1. Plywood

Plywood pallets are made from many thin layers of wood, pressed tightly under high temperature and pressure. During the pressing process, the temperature can reach over 100°C, enough to kill all types of insects or pathogens hidden in the wood. Therefore, plywood pallets do not need additional fumigation before export.

In addition to the advantage of being fumigated, plywood pallets are also lighter than natural wood pallets, easy to transport, less prone to warping, and suitable for many industries that require hygiene such as food, pharmaceuticals, electronics.

2. Wood composite pallets and non-wood materials

Wood composite pallets are made from crushed wood chips, mixed with glue, then pressed into a mold under high pressure and temperature. This process is similar to plywood production, ensuring that no harmful organisms remain in the product.

In addition, pallets made from non-wood materials such as plastic, metal, honeycomb paper, etc. are also in the fumigation-free group because they do not contain solid wood components. This is a popular choice in international logistics because of its durability, high reusability, and no restrictions when passing through border gates.

3. Processed materials do not need to be treated according to ISPM15

ISPM15 clearly stipulates: fully processed wood products such as MDF, HDF, OSB, plywood, or surface-coated wood... are exempt from fumigation treatment. The reason is that the temperature and pressure during the production process have destroyed all risks of spreading pests.

Thanks to this feature, businesses can use pallets made from the above materials for export without having to worry about the cost and time of fumigation, while still meeting international phytosanitary requirements.

International Standards ISPM15 and Fumigation

1. Acceptable Methods (HT, MB)

ISPM15 (International Standards for Phytosanitary Measures No.15) is an international standard that regulates the treatment of wood packaging material in international trade to prevent the spread of plant pests. According to ISPM15, there are two main accepted treatment methods:

- HT (Heat Treatment): Pallets or wood materials are placed in a treatment chamber at a minimum temperature of 56°C for 30 minutes at the core of the wood. This method kills fungi, insects and pathogens without the use of chemicals.

- MB (Methyl Bromide Fumigation): Pallets are placed in a closed environment and treated with Methyl Bromide gas for a specified period of time to kill pathogens. However, this method is increasingly limited due to its negative impact on the environment and human health.

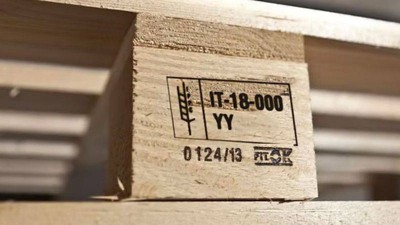

After treatment with HT or MB, pallets are stamped with the IPPC (International Plant Protection Convention) mark with the method symbol to certify that they meet ISPM15 standards.

2. Materials exempted from ISPM15 treatment

Not all wood packaging materials need to be treated according to ISPM15. Some types are exempt from fumigation or heat treatment because the nature of the material ensures pest safety, including:

- Plywood pallets, plywood, MDF, HDF, OSB ... because they have undergone high temperature processing, completely eliminating termites and microorganisms.

- Molded wooden pallets because they are produced from finely ground wood, heat-pressed at high pressure, no longer have a solid wood structure, so they are not a habitat for pests.

- Non-wood materials such as plastic, metal, pressed cardboard ... do not contain plant pathogens.

The reason these materials are exempt from treatment is because the manufacturing process has met the requirements of destroying pathogens, ensuring quarantine safety without the need for additional disinfection steps.

Why and when are pallets fumigated?

1. Technical and environmental reasons

Fumigation-free pallets help businesses save costs and time when exporting goods. Instead of having to put pallets through a costly and time-consuming fumigation process, using ISPM15-compliant materials from the beginning helps shorten the process. In addition, using fumigation-free pallets also limits negative impacts on the environment, especially when there is no need to use Methyl Bromide - a substance that damages the ozone layer.

Technically, fumigation-free pallets are often lighter, more durable and less prone to warping than solid wood, helping to optimize the transportation and storage of goods.

2. Applications in export and domestic

- Export: Fumigation-free pallets are very suitable for shipments that need quick customs clearance or are frequently exported to many countries with strict requirements on plant quarantine. Because they have met the standards, the pallets do not need to go through additional processing steps, reducing the risk of goods being held at the port.

- Domestic: In domestic transportation and storage, fumigation-free pallets are also popular due to their durability, lightness and hygiene safety, especially for the food, pharmaceutical and electronics industries.

Thanks to these advantages, fumigation-free pallets are becoming the priority choice of many businesses, ensuring compliance with international standards while optimizing logistics efficiency.

How to identify fumigation-free pallets

1. Identification by materials, signs, labels (IPPC logo, HT/MB symbol)

Fumigation-free pallets are usually manufactured from completely processed or non-wood materials, such as plywood, particle board, molded wood, or composite plastics. These materials have been treated at high temperature and pressure right from the production stage, eliminating the risk of carrying pathogens or pests, so no further fumigation is required.

In addition to the material factor, users can observe the stamp, mark or symbol printed directly on the pallet. According to ISPM15 standards, fumigation-free pallets usually:

- Do not have the MB (Methyl Bromide) or HT (Heat Treatment) symbol because they are not sterilized after production.

- Some types of non-wood pallets will not have the IPPC logo printed because they are not subject to wood quarantine, but processed wood pallets can still be printed to prove their origin.

- The color and surface are often uniform and smoother than untreated natural wood.

When importing or exporting goods, carefully checking the label helps businesses avoid returning goods or incurring additional processing costs at the port.

2. Tips for choosing the right pallet for your intended use

To choose the right fumigation-free pallet, you should:

- Determine the export market, each country has its own quarantine requirements, so you should consult customs regulations before choosing the type of pallet.

- Choose a standard size to optimize container space and reduce shipping costs.

- Prioritize reputable suppliers who provide clear documents and images of the material type and fumigation standards.

- Check the load capacity for heavy goods, thick plywood pallets or molded wood pallets will be safer than thin plastic pallets.

Benefits and notes when using fumigation-free pallets

1. Advantages in terms of cost and time

Using fumigation-free pallets helps to significantly save on fumigation treatment costs and shorten the time to prepare export goods. You do not need to wait for the fumigation process which lasts for 1-2 days and do not have to pay for this service. In addition, fumigation-free pallets also reduce the risk of damage to goods due to not being exposed to fumigation chemicals.

For businesses that export regularly, this advantage contributes to increasing the speed of goods turnover, improving the ability to meet urgent orders.

2. Situations to consider (such as customs conditions, international requirements)

Despite many benefits, fumigation-free pallets are not always suitable. Some countries still require quarantine certificates or additional treatment even if the pallet is in the fumigation-free group. In addition, if the goods are transported through many transit points, re-inspection requirements may arise, slowing down the delivery process.

Therefore, before deciding to use, businesses should:

- Verify the import regulations of each market.

- Prepare documents related to pallet production materials.

- Discuss in advance with the logistics unit to avoid risks when doing customs clearance procedures.

Conclusion

Fumigation-free pallets bring many benefits to businesses, especially in saving time and costs when exporting. Understanding the ISPM15 standard and identifying the right type of exempt pallets will help you be more proactive in the packaging process. Choose the right fumigation-free pallet to optimize the transportation process and ensure that the goods always meet international standards.