What is an RFID Pallet? Technology, Advantages, and Applications

RFID Pallets are becoming a modern solution to help businesses manage warehouses and supply chains more effectively. With the ability to accurately track each pallet in real time, this technology helps reduce loss, optimize inventory and increase the speed of goods circulation. This article will analyze in detail about RFID Pallets, their benefits and practical applications so that businesses can maximize their value!

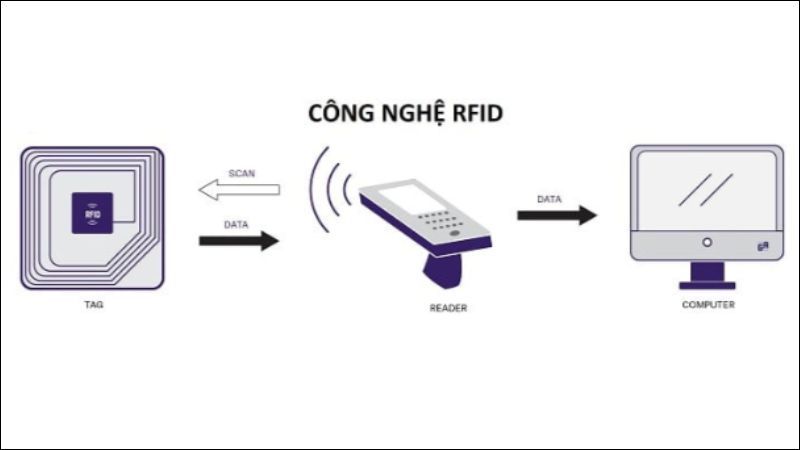

What is an RFID Pallet?

RFID Pallets are a combination of traditional pallets and Radio Frequency Identification (RFID) technology. Instead of just using pallets to store, lift and transport goods, these pallets are attached with RFID tags to store and transmit data. Thanks to that, businesses can accurately track the location, status and movement of pallets throughout the supply chain.

Compared to the barcode labeling method, RFID Pallets stand out in their ability to scan multiple tags at the same time, read data remotely and minimize errors due to manual operations. This is an important foundation for building a more modern, automated and transparent warehouse management system.

Benefits of using RFID Pallets

1. Increase tracking accuracy & reduce loss

With RFID Pallets, every pallet movement is automatically recorded. Businesses can know exactly which pallets are in the warehouse, which pallets have been exported and which pallets are in transit. This limits the loss of goods, confusion in inventory, and at the same time increases accuracy to almost absolute compared to manual management.

2. Optimize warehouse operations & reduce labor costs

The import and export process using RFID Pallets is quick thanks to automatic scanning, without the need for staff to count each pallet. This helps reduce labor pressure, save warehouse operating costs and shorten order processing time. When the number of pallets is large, the optimization benefits are even more evident.

3. Improve inventory management and import-export flow

RFID pallets help businesses grasp inventory in real time, easily determining the exact quantity of goods in the warehouse. At the same time, the system also allows analysis of the flow of goods from import to export, helping to adjust the supply and transportation plan reasonably. Thanks to that, businesses minimize the situation of excess or shortage of inventory.

4. Increase the ability to analyze data & make decisions

Data from RFID pallets is stored and synchronized into the management system, providing valuable information for analysis. Businesses can monitor the performance of goods circulation, evaluate the speed of pallet turnover, thereby optimizing logistics plans. This is an important step to upgrade warehouse management in a smart direction, based on data instead of emotions.

Popular Technology and Standards

1. GS1 EPC Class 1 Gen 2 – UHF RFID standard

In the field of Pallet RFID, the GS1 EPC Class 1 Gen 2 (UHF RFID) standard is considered the most important platform today. This standard operates on the 860–960 MHz frequency band, allowing reading tags at long distances (up to meters) and the speed of identifying thousands of tags per second. With pallets, this helps the system to scan the entire shipment in just a few seconds, supporting optimal warehouse management, reducing errors and increasing supply chain efficiency. In addition, the EPC Gen 2 standard also ensures global compatibility, easy to deploy in international warehouses.

2. Passive vs. active tags for pallets

Pallets RFID often use two main types of tags: passive and active.

- Passive tags do not have batteries, are activated when receiving waves from RFID readers. The advantage is low cost, easy to attach to large pallets, suitable for warehouses with fast turnover.

- Active tags have built-in batteries, actively emit signals, so the reading range is longer (from several tens of meters). This type is often applied to pallets that need continuous monitoring in logistics, long-distance transportation or environments with a lot of metal and interference.

When implementing, businesses need to consider the goals and costs to choose the right type of tag, ensuring both savings and achieving the desired tracking efficiency.

3. Outstanding product lines: iGPS, Xerafy Cargo, Scrilbit

Currently, many RFID Pallet solutions have been commercialized on the market:

- iGPS: uses plastic pallets with built-in RFID, helping to increase durability and reduce reuse costs. This is a popular solution in consumer goods supply chains.

- Xerafy Cargo: focuses on industrial RFID tags with heat resistance, shock resistance and good performance in harsh environments. This product is suitable for international logistics and container transport.

- Scrillet (Venatrust): designed specifically for wooden pallets, easily integrates RFID in traditional warehouses where wooden pallets still account for a high proportion. This solution helps businesses take advantage of existing infrastructure while still modernizing management.

Practical applications in the supply chain

1. Track pallets in the warehouse and during transportation

RFID pallets help businesses monitor the location of pallets in the warehouse in real time and throughout the entire transportation process. Thanks to RFID tags, each pallet is automatically identified when entering/exiting the gate, reducing lost goods and optimizing goods flow management.

2. Integration with WMS/ERP systems

When integrating RFID pallets with WMS or ERP, pallet data is instantly synchronized, supporting accurate inventory management and better demand forecasting. This combination helps automate the import - export - storage process, reducing dependence on manual recording.

3. Applications in global logistics - Xerafy example

In reality, many global logistics corporations apply RFID pallets to optimize the supply chain. Typically, Xerafy deploys RFID-tagged pallet solutions in international transportation, helping to reduce management costs, increase transparency and traceability.

4. Durable wooden pallets – e.g. Vena Trust Scrilbit

One of the special applications is the RFID-enabled wooden pallet, e.g. Vena Trust Scrilbit. This solution combines the durability of wood with smart identification technology, suitable for harsh environments, while providing the ability to track each shipment in detail.

Challenges & Notes when deploying RFID Pallets

1. Initial investment costs and ROI

Implementing RFID Pallets requires initial costs for tags, readers and management systems. However, ROI will be clearly demonstrated through reduced losses, improved operational efficiency and supply chain optimization. Businesses need to carefully calculate the capital recovery roadmap before deployment.

2. Infrastructure and integration of existing systems

For RFID Pallets to be effective, the system must be compatible with warehouse management software (WMS) and ERP. If the infrastructure is not synchronized, businesses will have difficulty in synchronizing data and monitoring in real time.

3. Security & data protection issues

Data from RFID Pallets contains important information about goods, shipments and supply chains. Without a good security solution, businesses are at risk of data leakage or unauthorized access. Therefore, data encryption and strict authorization are priorities.

4. Frequency compatibility and international standards

Each region has its own regulations on RFID frequencies. When applying RFID Pallets in the global supply chain, businesses need to ensure that the equipment is compatible with international standards such as EPC Gen2 for seamless operation and to avoid wave conflicts.

Future trends of RFID Pallets

1. Combining RFID with BLE and computer vision

In the future, RFID Pallets will not only stop at traditional RFID tagging but also be combined with BLE (Bluetooth Low Energy) and computer vision. This integration helps monitor pallets in real time, determine more accurate locations and automatically identify pallet status through images, minimizing errors in management.

2. Using RFID in smart pallets and automation

The development of smart pallets allows RFID to operate as part of warehouse automation systems. Thanks to direct connection with robots, conveyor belts and WMS/ERP systems, RFID Pallets help businesses shorten processing procedures, increase import and export speed and reduce operating costs. This is an important step towards the 4.0 smart warehouse model.

3. Towards a more sustainable and transparent supply chain

The application of RFID Pallets in logistics also supports a sustainable supply chain. Each RFID-attached pallet can record its movement history, usage status and life cycle, making it easy for businesses to trace its origin and optimize reuse. This not only reduces waste but also increases transparency, meeting the increasing demands of the global market.

Conclusion

Pallets RFID is becoming a modern technology solution that helps businesses optimize supply chain management and minimize operational losses. The application of Pallet RFID not only brings transparency but also improves the efficiency of real-time tracking of goods. This is an inevitable trend for businesses that want to increase their competitiveness in the future.