Heavy Duty Pallets: Plastic vs Wood Comparison, Guide to Choosing the Right One

High-load pallets are increasingly becoming the preferred choice in modern logistics, manufacturing and warehousing activities. With the ability to withstand loads from thousands to tens of thousands of kilograms, these pallets help optimize space and ensure safety during transportation. Businesses using high-load pallets not only save labor costs but also improve warehouse operating efficiency. The following article will analyze in detail the characteristics, advantages and how to choose the right pallet for each need!

What is a high-load pallet?

High-load pallets are specially designed pallets to withstand heavy weight, often used in warehouses, factories or logistics industries that need to store and transport heavy goods. Unlike conventional pallets, high-load pallets have a sturdy structure, often made of thick wood, hard plastic or steel, ensuring safe support when stacked or moved by forklift.

This type of pallet usually has a load capacity of 1,000 kg or more, suitable for heavy industrial production, chemicals, construction materials, machinery or large-volume export goods. Thanks to its outstanding load-bearing capacity, high-load pallets help businesses save warehouse space, protect goods and improve efficiency in the logistics process.

Common load levels for pallets

1. Under 1,000 kg (light load)

This type of pallet is suitable for products with small volumes, often used in retail stores, consumer warehouses or temporary storage of goods. Although classified as light load, this pallet still ensures safety and is easy to move by hand pallet truck or electric forklift.

2. 1,000–3,000 kg (medium load)

Medium load pallets meet the needs of most manufacturing and transportation businesses. With a capacity of one to three tons of goods, this type of pallet balances durability, cost and flexibility. This is also the most commonly used group in industrial warehouses.

3. Over 3,000 kg (heavy / high load)

These specialized high-load pallets are often used for heavy industrial goods, mechanical components, machinery or export containers. They have a sturdy reinforced structure, superior load-bearing capacity and are often combined with virgin plastic pallets or thick wooden pallets to ensure absolute safety during storage and transportation.

Comparing high-load plastic and wooden pallets

1. Advantages and disadvantages of each type

- High-load plastic pallets: Made from virgin HDPE or PP plastic, good load-bearing capacity and termite-free. The advantages are long-term durability, easy to clean, moisture-proof and suitable for cold storage. The disadvantage is that the initial investment cost is higher than that of wooden pallets.

- High load wooden pallets: The biggest advantage is low cost, easy to make new ones according to required size, suitable for one-time export goods. However, wooden pallets are easily damaged when exposed to humid environments, have a short lifespan and are susceptible to termites and mold.

2. Application by industry (logistics, cold storage...)

- Logistics & warehousing industry: High load plastic pallets are often preferred due to their durability, ability to be reused many times and international standards.

- Cold storage & food: Plastic pallets are suitable because they are water-resistant, chemical-resistant, and do not deform at low temperatures.

- Exporting goods & temporary storage: High load wooden pallets are still chosen due to their low cost, meeting long-distance, one-time shipments.

Criteria for choosing suitable high load pallets

1. Static & dynamic loads suitable for needs

Static load is the ability to withstand force when the pallet is stationary on the floor; dynamic load is when the pallet is moved by forklift or cart. Users need to balance actual needs to choose high-load pallets to ensure the safety of goods.

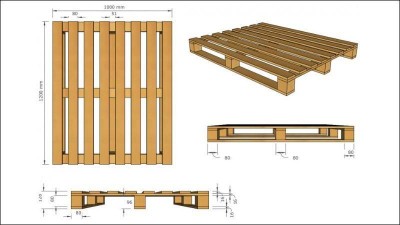

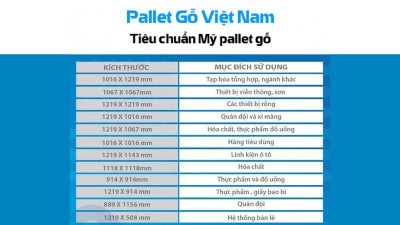

2. Size, structure, material

High-load pallets must have the same size as the storage shelves and shipping containers. The floor structure (closed surface, open surface, 4-way lifting) also determines the efficiency of use. In addition, HDPE plastic or hardwood materials will affect the lifespan and load capacity.

3. Forklift compatibility, storage

A quality high-load pallet needs to be compatible with forklifts, ensuring easy movement in the warehouse. At the same time, the design must be suitable for the storage rack system, avoiding pallet jams or not being able to withstand the correct load.

Where to buy high-load pallets?

Green Pallet is a reputable address providing high-quality high-load pallets, trusted by many domestic and foreign enterprises. With a sustainable and innovative orientation, Green Pallet not only provides optimal storage and transportation solutions but also meets strict international standards.

- Sustainable & innovative brand: Green Pallet comes from the philosophy of “Green” (sustainability) and “Innovation” (innovation), becoming a trusted partner of many businesses in the logistics, manufacturing and export industries.

- Prestigious international certification: Products meet FSC, ISO 9001:2015, ISO 14001:2015 standards, affirming quality, safety and responsibility to customers and the community.

- Energy saving & emission reduction: Solar-powered systems combine energy-saving solutions in production, helping to reduce CO2 and aim for carbon neutrality.

- Modern automated production line: Closed production process, fully automated, ensuring each high-load pallet product is uniform, accurate and meets export standards.

- Safe & environmentally friendly materials: Green Pallet uses recycled wood and formaldehyde-free MDI glue, which reduces natural forest exploitation and is safe for human health and the environment.

Conclusion

Green Pallet provides high-quality high-load pallet solutions, meeting diverse storage and heavy transportation needs in many industries. With durable load-bearing capacity and optimal design, the product helps businesses save costs and increase logistics efficiency. Choosing the right type of high-load pallet not only ensures the safety of goods but also improves operating productivity. Let Green Pallet accompany you on the journey to build a sustainable and effective warehouse system!