Smart Warehouse Organization: Tips and Principles You Need to Know

Scientific warehouse arrangement not only helps save time and costs but also contributes to improving overall operational efficiency. In the increasingly competitive business context, a smartly organized warehouse system will create a clear advantage for the business. However, not everyone clearly understands the principles and methods of effective warehouse arrangement. The following article will help you grasp the warehouse optimization strategies from basic to advanced!

Principles and methods of effective warehouse arrangement

To operate a warehouse scientifically and save costs, correctly applying the principles of warehouse arrangement is a key factor. Not only does it help control inventory accurately, reasonable arrangement also optimizes the import - export process and minimizes errors during operation.

1. Principles of FIFO, LIFO and FEFO in warehouse management

Choosing the right principle of arrangement by time or expiry date will help businesses control goods effectively and avoid expired inventory.

2. Arrange by SKU code and divide warehouse areas

Classifying goods by SKU code combined with clear division of areas makes it easy to look up, search and shorten order processing time.

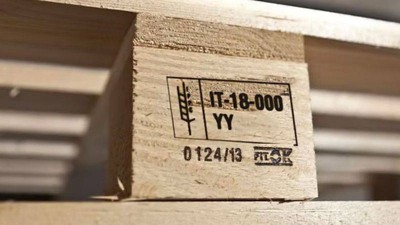

3. Optimize warehouse space - use shelves, pallets and aisles

Arranging shelves and pallets reasonably and ensuring clear aisles helps maximize warehouse space while still ensuring safety in transportation.

4. Managing defective goods, returned goods and separate storage areas

Separating substandard goods into separate areas will help avoid confusion with goods in use and ensure that operating processes are strictly controlled.

Flexibly selecting and applying warehouse arrangement methods not only helps increase labor productivity but also plays an important role in controlling the flow of goods effectively. Thereby, minimizing risks and saving long-term costs for businesses.

Smart warehouse arrangement tips and strategies

Warehouse arrangement is not only a problem of space but also the key to help businesses optimize operational efficiency. A scientifically organized warehouse system will reduce search time, limit errors and improve inventory management efficiency. Below are some tips and strategies to help you organize your warehouse more intelligently and practically during operations.

1. Mark the location of goods and create a clear warehouse diagram

Clear location labels combined with an overall diagram help employees easily identify areas, shorten search time and limit confusion.

2. Arrange by import and export frequency and weight of goods

Frequently imported and exported goods should be placed in an easily accessible location; heavy goods should be placed below to ensure safety and convenience when moving.

3. Regularly check and update warehouse information

Maintaining regular inventory helps detect data discrepancies and accurately control inventory, avoiding loss or waste of storage space.

4. Applying technology in warehouse management

Warehouse management software, barcodes, RFID or automated systems help speed up data processing, minimize manual errors and support quick decision making.

When you know how to flexibly apply the above strategies, warehouse arrangement will no longer be a complicated problem but will become a competitive advantage in logistics and business operations.

Common mistakes in warehouse arrangement and how to fix them

Improper warehouse arrangement can cause many consequences such as wasted space, difficulty in controlling goods, and even slowing down the delivery process. Here are some common mistakes that many businesses encounter and suggestions for effective solutions:

- No clear warehouse layout -> Need to build a detailed warehouse layout map and update when there are changes.

- Arranging goods not according to inventory management principles -> Apply FIFO, LIFO or FEFO depending on the nature of the product.

- Not clearly dividing areas for each type of goods -> Set up separate areas for new goods, defective goods, returned goods, etc.

- Abusing horizontal space, ignoring height -> Take advantage of warehouse height with a safe multi-level shelf system.

- Lack of periodic inventory -> Set up an inventory schedule and compare inventory with management software.

- Aisles are too narrow or unreasonable -> Design aisles wide enough, convenient for transportation by forklift or manually.

Conclusion

Arranging warehouses scientifically not only helps optimize space but also improves operational efficiency and goods control. Whether your warehouse is large or small, proper organization always brings long-term value to your business. Instead of following your gut, apply modern warehouse management principles to avoid unnecessary mistakes. A neat warehouse system is the foundation for sustainable business operations!