Export wooden pallet standards: Dimensions, materials and detailed processes

Export goods packaging cannot be without wooden pallets that meet international standards. However, not all pallets are qualified to be accepted in markets such as the US, EU or Japan. Understanding the standards for wooden pallets for export will help businesses avoid customs risks, save costs and ensure the safety of goods. The following article will help you understand important regulations and choose the right type of pallet!

What are the standards for wooden pallets for export?

Export wooden pallets are pallets that are manufactured and processed according to technical standards to meet the requirements of international freight transport. These standards are not only related to size or load capacity, but also include strict regulations on biological treatment to prevent pests from moving across borders. Compliance with the standards for wooden pallets for export helps goods to be cleared through customs smoothly, minimizing the risk of inspection and retention at the port of entry.

Current popular export wooden pallet standards

1. ISPM 15 standard on heat treatment or fumigation

ISPM 15 (International Standards for Phytosanitary Measures No. 15) is an international regulation on the treatment of wood materials used in cross-border transportation of goods. According to this standard, wooden pallets must be treated with heat (HT) or fumigated with methyl bromide gas (MB) to destroy pathogens and harmful insects.

After treatment, the pallet must be stamped with ISPM 15 certification along with the country code and licensed treatment unit. This is a mandatory requirement in most importing countries in the world.

2. Pallet size standards by market (EU, US, Japan)

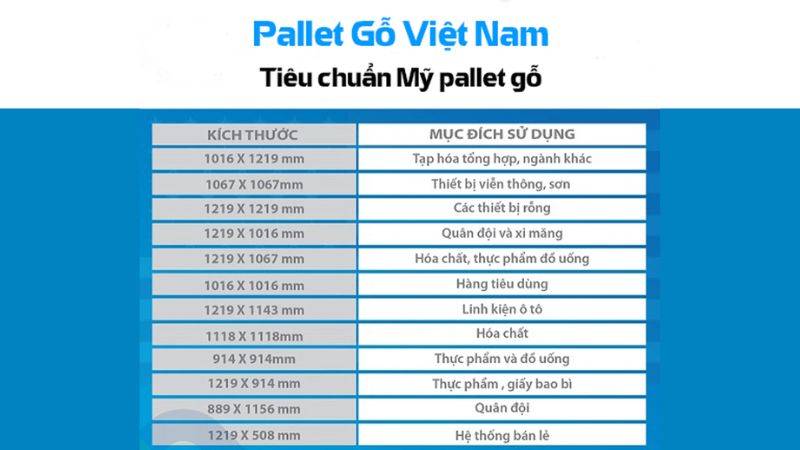

Each region in the world has its own pallet size standards to suit the warehouse system, containers and means of transport:

- The European market commonly uses Euro pallets (EPAL) with a size of 1200 x 800 mm.

- In the US, the GMA pallet standard (Grocery Manufacturers Association) has a size of 1219 x 1016 mm.

- The Asian region often uses pallets of 1100 x 1100 mm or 1000 x 1200 mm, flexible for standard containers.

Choosing the right size helps optimize the space for stacking goods and avoids adjustment costs when going through the port.

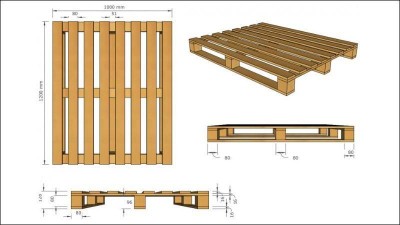

3. Packaging and load-bearing standards when exporting

In addition to size and biological treatment, export pallets also need to ensure load-bearing capacity suitable for the type of goods being transported. Loads are often divided into static loads, dynamic loads and rack loads. Pallets must be sturdy enough to hold the goods firmly during transportation, loading and unloading and storage. At the same time, the packaging must ensure that the goods are firmly fixed on the pallet with PE film, straps or corners to avoid displacement during transportation. This is an important factor to minimize damage and protect the value of goods throughout the export journey.

Export wooden pallet sizes by region

Pallet sizes are not the same between countries and regions, because each market has its own standards based on the method of transportation and packaging specifications. Using the right type of pallet not only helps to stack goods neatly, optimize space but also avoids the risk of being rejected at the import port.

1. European standard pallet (EUR, EPAL): 1200 x 800 mm

This is the most commonly used pallet type in the EU market, managed and certified by the European Pallet Association (EPAL). The 1200 x 800 mm size is designed to fit European containers, forklifts and racking systems. EUR pallets require high durability, are handled according to ISPM 15 standards and have a clear certification mark.

2. Standard American Pallet (GMA): 1219 x 1016 mm

The US and Canadian markets often use 48 x 40 inch pallets (equivalent to 1219 x 1016 mm), called GMA (Grocery Manufacturers Association). This type of pallet is suitable for the food, consumer and domestic logistics industries in North America. This size is optimal for 40-foot containers and warehouse systems in the US.

3. Asian standard pallets: 1100 x 1100 mm and 1000 x 1200 mm

In Asian countries such as Japan, Korea, China or Vietnam, the two most popular pallet types are 1100 x 1100 mm and 1000 x 1200 mm. The 1100 x 1100 mm type is often used in the light and electronics industries, while the 1000 x 1200 mm type is suitable for exporting heavy or bulky goods. Flexibility in use makes it easy for Asian businesses to customize according to export goals.

Technical requirements for export wooden pallets

To ensure that wooden pallets can legally circulate across countries, it is necessary to strictly comply with technical requirements related to materials, processing and certification. Violations of standards can result in goods being returned, causing serious damage to exporting businesses.

1. Suitable wood material (acacia, eucalyptus, pine...)

Wood used to make pallets must have good mechanical strength, little warping, easy to process and good bearing capacity. Commonly selected wood types include acacia, pine, eucalyptus... These are types of wood with high stability, easy to process and meet international standards when exporting.

2. Anti-termite treatment, standard humidity

Before being put into use, wooden pallets must be treated to kill termites, bacteria and mold. There are two common treatment methods: heat treatment (HT) and fumigation with methyl bromide (MB). In addition, the wood moisture content must be controlled below the prescribed level (usually

3. Treatment certification mark (HT, MB) & national mark according to ISPM 15

Each wooden pallet after treatment must be stamped with a certification mark according to the regulations of ISPM 15 standard. This mark shows the country code, production unit code and treatment method (HT or MB). This is the legal basis for customs and quarantine agencies of countries to approve imported pallets. Without this mark, the shipment is very likely to be detained or requested for re-processing.

Export wooden pallet sizes by region

Pallet sizes are not the same between countries and regions, because each market has its own standards based on the method of transportation and packaging specifications. Using the right type of pallet not only helps to arrange goods neatly, optimize space, but also avoids the risk of being rejected at the import port.

1. European standard pallet (EUR, EPAL): 1200 x 800 mm

This is the most commonly used pallet type in the EU market, managed and certified by the European Pallet Association (EPAL). The size of 1200 x 800 mm is designed to fit containers, forklifts and racking systems in Europe. EUR pallets require high durability, are handled according to ISPM 15 standards and have a clear certification mark.

2. Standard American Pallet (GMA): 1219 x 1016 mm

The US and Canadian markets often use 48 x 40 inch pallets (equivalent to 1219 x 1016 mm), called GMA (Grocery Manufacturers Association). This type of pallet is suitable for the food, consumer and domestic logistics industries in North America. This size is optimal for 40-foot containers and warehouse systems in the US.

3. Standard Asian Pallets: 1100 x 1100 mm and 1000 x 1200 mm

In Asian countries such as Japan, Korea, China or Vietnam, the two most popular pallet types are 1100 x 1100 mm and 1000 x 1200 mm. The 1100 x 1100 mm type is commonly used in the light industry and electronics, while the 1000 x 1200 mm is suitable for exporting heavy or bulky goods. The flexibility in use makes it easy for Asian businesses to customize according to export goals.

Technical requirements for exported wooden pallets

To ensure that wooden pallets can legally circulate across countries, it is necessary to strictly comply with technical requirements related to materials, processing and certification. Violations of standards can cause goods to be returned, causing serious damage to exporting businesses.

1. Suitable wood material (acacia, eucalyptus, pine ...)

Wood used to make pallets must have good mechanical strength, little warping, easy to process and good bearing capacity. Commonly selected wood types include acacia, pine, eucalyptus... These are types of wood with high stability, easy to process and meet international standards when exporting.

2. Anti-termite treatment, standard humidity

Before being put into use, wooden pallets must be treated to kill termites, bacteria and mold. There are two common treatment methods: heat treatment (HT - Heat Treatment) and fumigation with methyl bromide (MB). In addition, the wood moisture content must be controlled below the prescribed level (usually

3. Treatment certification mark (HT, MB) & national mark according to ISPM 15

Each wooden pallet after treatment must be stamped with a certification mark according to the regulations of ISPM 15 standard. This mark shows the country code, production unit code and treatment method (HT or MB). This is the legal basis for customs and quarantine agencies of countries to approve imported pallets. Without this mark, the shipment is very likely to be detained or requested for reprocessing.

Notes when choosing wooden pallets for export

1. Suitable for goods and form of transportation

The selection of wooden pallets must be based on the characteristics of the goods: weight, size, fragility and storage conditions. For bulky or heavy goods, priority should be given to wooden pallets with a sturdy structure and high load-bearing capacity. At the same time, the form of transportation such as sea, air or container also affects the type of pallet to be used to optimize space and cost.

2. Meet customs and quarantine requirements of the importing country

Each country has its own regulations on quarantine and pallet packaging. In particular, many markets such as the EU, the US, and Japan require pallets to be heat-treated or fumigated according to ISPM 15 standards. If they do not meet the requirements, the shipment may be refused import or destroyed at the port of arrival. Therefore, businesses need to carefully check the regulations of the importing country before choosing a pallet.

3. Compare wooden pallets vs plastic pallets in export

Wooden pallets are often low cost, easy to produce and suitable for most export items. However, plastic pallets have the advantage of durability, do not need to be treated for termites, are lighter and easier to clean. Although the investment cost is higher, plastic pallets are preferred in industries with strict hygiene requirements such as food and pharmaceuticals. Therefore, businesses should carefully consider the cost, product characteristics and market requirements.

Frequently asked questions about wooden pallets for export

1. Are wooden pallets required to be heat treated?

In most cases, yes. According to ISPM 15 of the International Plant Protection Organization (IPPC), wooden pallets used for export must be heat treated (HT) or fumigated (MB) to destroy termites and pests. Importing countries often require accompanying treatment certificates, so heat treatment is almost mandatory when exporting.

2. Can you make your own pallets according to export standards?

Businesses can completely make their own pallets if they have the right machinery, processes and treatment certificates. However, if they do not strictly control the quality, self-made pallets may not meet quarantine requirements, leading to the risk of being returned. Therefore, a safer solution is to order pallets from reputable units that have been granted ISPM 15 treatment codes.

3. How to identify wooden pallets that meet ISPM 15 standards?

Patlets that meet ISPM 15 standards will have a mark stamped directly on the wood body, including the country code, the treatment code of the manufacturing unit, the treatment symbol (HT or MB) and the IPPC logo. This is a mandatory and clear identification mark. When exporting, you should carefully check the pallet batch to ensure that all have valid stamps and are not blurred or missing.

Reputable wooden pallet supplier in Vietnam

When choosing wooden pallets for export or storage activities, finding a reputable supplier is a decisive factor for quality and operational efficiency. Among the prominent units today, GreenPallet (under Greenovation Packaging) is known as a pioneer brand in the production of environmentally friendly molded wooden pallets.

More than just supplying pallets, GreenPallet offers optimal transportation solutions, aiming for a green and sustainable logistics model. With a diverse molding system, high customization capabilities and a production capacity of up to 3 million pallets per year, this business fully meets the strict requirements of many different industries — from agricultural exports to electronics and mechanics. GreenPallet is currently a trusted partner of many large enterprises that are aiming to standardize the supply chain in a modern and environmentally friendly direction.

- Sales office: No. 95/5 Thao Dien, An Khanh Ward, Ho Chi Minh City, Vietnam.

- Headquarters and factory: No. 68-69, Road No. 7, Long Thanh Industrial Park, An Phuoc Commune, Dong Nai Province.

- Hotline: +84 283 898 9779 - +84 79 66 888 79

Conclusion

Complying with export wooden pallet standards is an important step to ensure the safety of goods and avoid being returned when passing through international border gates. Each market has its own regulations, so choosing the right type of pallet is not subjective. If you are looking for a standard wooden pallet solution, GreenPallet is a unit worth considering. Proper investment in packaging will help protect the reputation and long-term business efficiency of the enterprise.